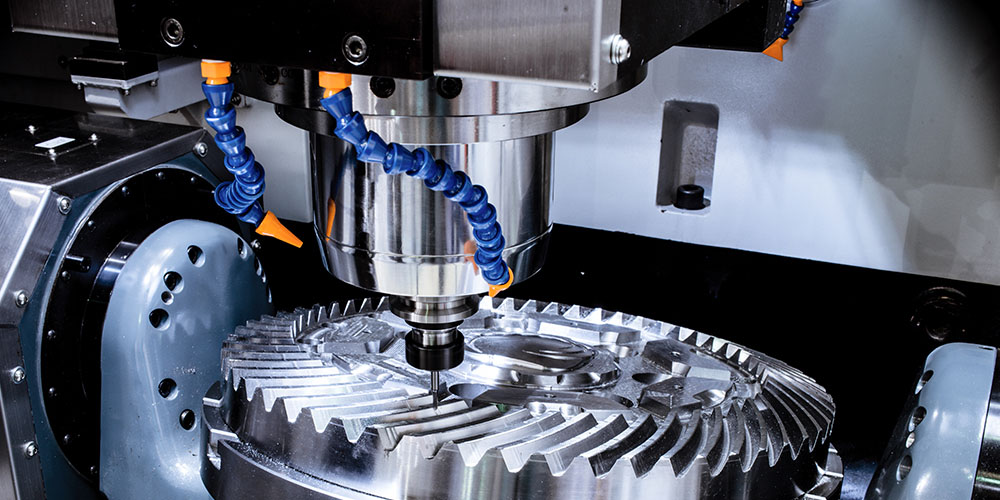

Today, most manufacturing industry relies on CNC machining. This includes various operations that use engineering-controlled equipment such as routers, vertical and shaping machines. Millers and lathes are also part of the processes that rely on CNC milling services.

The CNC machining platform provides various types of financial and production pros over the typical conventional method. In the manual world of lathing, there must be a skilled laborer for every machine. On the other side, in the CNC machining world, one skilled person can operate various machines, and everything will just run out fine, and the esult will be the best.

The CNC machining world produces a broad range of various metal as well as plastic elements. These structures have certainly become a huge part of business, coupled with the general environment. For that reason, several sectors need consistent as well as complicated cuts.

Some of the sectors include:

- Hospitality

- Metalwork

- Publishing

- Manufacturing

- Electronics

Why CNC Machining is better than conventional machining

CNC machining, as well as conventional machining, are designed to help you achieve the same objective. The primary difference between the two is that one is automated while the other is labour-intensive and must be run by people.

The basic difference between these two is that one is fully automated while the other is manual and must be operated manually. Then there is speed, the production rate, coupled with accuracy, which are additional pros of using a CNC machine over the manual one.

With CNC machining, a skilled laborer programs the software so that there is a cut on the part.

With conventional machining, a skilled worker must take all the necessary steps in setting up the machine before it begins to operate.

In the manual operation setting, a laborer must set the machine’s gears while with CNC machining, no gears are used.

Conventional machining costs lesser and is often used for smaller quantities of projects. On the other hand, CNC machining is used for slightly higher quantities. This also implies that it is not that cost-effective in the long run.

You can try imagining a hypothetical part where a component should concave or various convex arcs over and above. An automated machine will use about three tools to dice the part while a traditional machine would need up to five tools and more time to cut the same size of tool.

Why CNC machining is right for you

CNC machining is a common method for prototyping products. It is used in manufacturing and production. Other ways of making a prototype include the 3D printing technology that uses the FDM to design products. Other than that, there is the 3D technology that includes the prominent stereolithography and selecting laser sintering.

Final Thoughts

Suppose you are responsible for planning the design and manufacturing of various metal parts and components; you should now know the pros of using CNC machining over traditional or conventional manufacturing methods. Although it is an expensive option, it also comes with several pros, such as saving time and efficiency in several ways.