How Rapid Tooling Provides a Competitive Edge

Are you looking to market products faster? You’ll need rapid tooling to ensure that parts are available for testing. The manufacturing industry is quickly evolving, thanks to the technology innovations in recent years, and among them is rapid tooling. But what is it, and what are rapid tooling advantages?

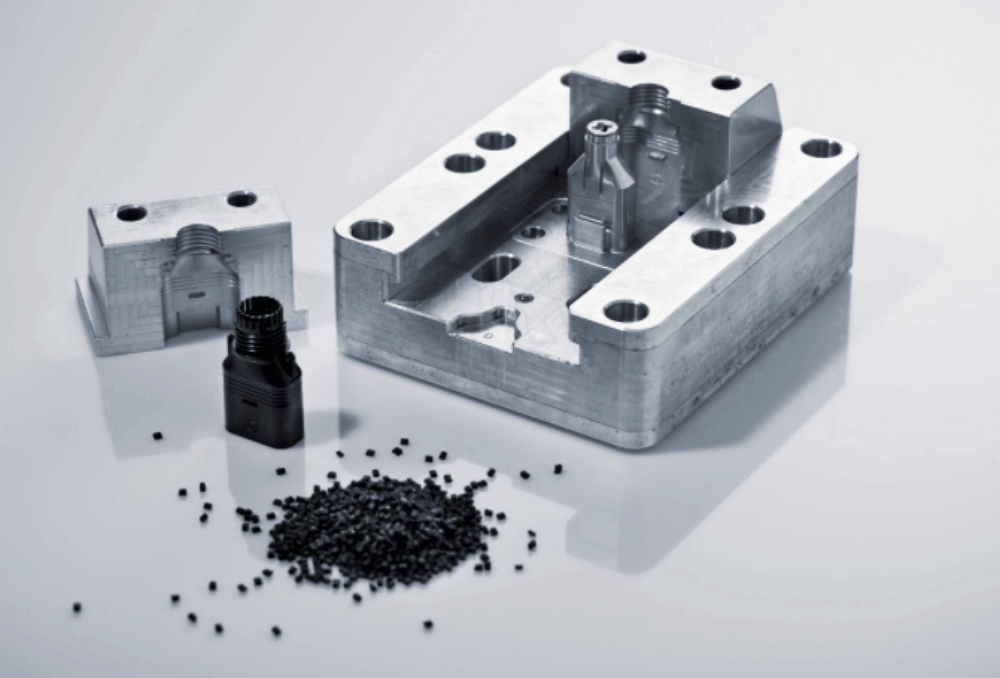

Ideally, rapid tooling is a technology that’s used to enable one to produce a product or tool quickly. It provides a faster means between the fabricated product and the design creative ideas. In addition, Rapid Tooling (RT) can be used in preparing parts for a functional model from CAD data within a short period at a low cost.

Advantages of Rapid Tooling

Rapid tooling is mostly used for injection molded products. Therefore, if you’re looking to reduce your cost of tooling, then rapid tooling is the best way to go. Some of the advantages of rapid tooling include:

Speed

One of the most significant benefits of rapid tooling is merely speed. Given that digital manufacturing technologies such as CNC machining and additive manufacturing can be used in creating molds within a very short period, rapid tooling providers can provide fast turnarounds on the products that are made with such molds.

Therefore, it means that for a business, one can get the products faster and then deliver them sooner into the market.

Cost Savings

Another advantage of rapid tooling is the fact that it’s cost-saving. Ideally, the parts that are produced in rapid tooling are synonymous with full-scale production. The parts can be used for stress and impact testing. Therefore, from the resting results, one can determine changes that are required before getting into the expansive process.

Provides Innovation Opportunity

One thing for sure about rapid tooling is that it gets rid of conventional tooling; therefore, initiating several opportunities that one can improve. For instance, traditional prototyping would usually take a long period as it requires making the prototype tooling.

With rapid tooling, designers have the option of conceiving complex geometrics, which is otherwise impossible to develop when it comes to conventional prototyping. Therefore, there’s an excellent opportunity to improve innovation.

Production of Various Products

There’s no denying that rapid tooling is one of the fastest means that can be used to produce the parts and get them into the market earlier. Additionally, it facilitates the production of several products in a plethora of materials.

Moreover, rapid tooling can be used to trouble existing problems. Also, in recent times it has been applied in creating molds for commercial operations. It’s usually the case as the lag time is always limited between the start and finish. Furthermore, rapid tooling has an advantage given that it’s used for particular small quantity needs, such as prototyping.

Nevertheless, the alternate methods usually need precious resources and time; therefore, rapid tooling becomes a quicker means of producing the required products. Companies have the chance to produce commercial products quickly, thanks to the advantages of rapid tooling. The benefits to consider rapid tooling is unlimited, low cost, effective, and quick.